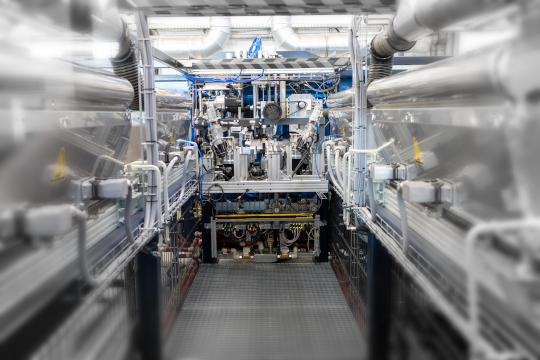

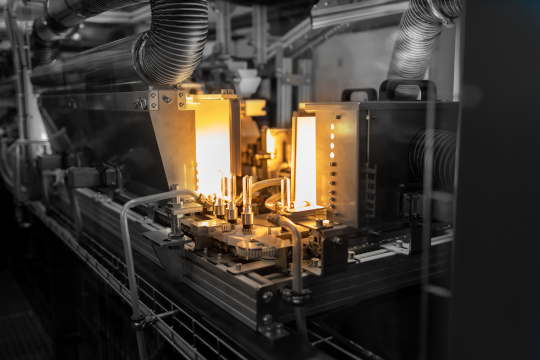

| CUSTOMER-ORIENTED INNOVATION Based on more than 20 years of pure Hungarian know-how and manufacturing experience, our main focus in designing and manufacturing POLIOL bottle blowing machines is to build machines that provide our customers with time-tested value and stable production capacity. Our state-of-the-art technology solutions will provide our customers with convenience, productivity and cost-efficiency at competitive prices for many years to come. Why POLIOL: Based on our market surveys and customer feedback, the three most important features of POLIOL Linear Arrangement Bottle Blowing Machines are: Strong frame The outstanding stability of our machines starts with a strong frame. We place particular emphasis on the material and design of the frame. This ensures that our machines are not vulnerable when moving or in operation. This makes them resistant to the forces around the clamping tool over millions of cycles. Solid closing tool For our machines to be able to work at high output, producing up to 50 million bottles a year, they must be equipped with a strong, expertly designed capping tool, made from high quality materials, ideally sized and with the right thickness. That's why our closing tools are among the most reliable in today's range. Reliable operation The reliable and fast operation of our machines is ensured by the electronic and pneumatic components and equipment from the best manufacturers on the market today, and by the state-of-the-art technical solutions used.

Servicing & training The satisfaction of our customers is important to us, so we consider it a fundamental task to ensure that future users and operators of our machines have the necessary knowledge and skills to learn the operation and maintenance procedures related to the operation. To this end, we support our customers with practical training and documentation during the handover of the machines at the production plant and during on-site commissioning, and later on with online training. We consider the continuous servicing of our machines to be of paramount importance. In the event of any reported faults, we will start work immediately. Our maintenance team will first inspect the machine remotely (if available). It is also possible to check the operation of the machine via the Internet and suggest possible solutions. Our team will arrive on time on the agreed date. We always keep in stock other products that are subject to wear and tear and most in use.. |

|